PT series

Application Note

PT series

EV/HEV fuses rated 100 - 500 A, DC 450 - 500 V

The PT series started with a rated current of 100 to 350 A at DC 450 V, which have been adopted for a wide range of applications, including applications in the new automotive era.

Most recently, the PT4065, a new model with a rated voltage of DC 500 V and a rated current of 500 A, was added to this series, expanding the product lineup for EV/HEV.

Here, we introduce development background, construction, specifications, the reasons for recommendation, and applications of the PT series.

- SOC Group:

- SOC Corporation

SOC America

SOC Asia

SOC Europe

Applications and features

Applications:

High voltage drive circuits and traction batteries of automobiles (EV, HEV, PHV, and FCV) and electric construction machineries

Storage batteries for photovoltaic systems and UPS

DC-DC converters, inverters / motor drivers, UPS for industrial machineries

Features:

Compact fuses with high voltage, large current and high breaking-capacity ratings

Long-term reliability to withstand various environmental durability tests at the vehicle level such as vibration and shock, high and low temperatures

High coordination with other protection devices such as relays

Development background

The automotive industry is undergoing a once-in-a-century revolution.

CASE is the abbreviation of keywords, which symbolically explains the areas of technological innovation: Connected, Autonomous, Shared, and Electric.

SOC first released the PT series (PT2035, PT2545, PT3050) for the protection of a broad range of electric circuits and electric devices such as traction batteries, high-voltage drives and auxiliary circuits.

Most recently, we added the PT4065 which has the highest current, voltage, and breaking ratings in the PT series.

Industrial fuses were originally designed on the premise that they would be installed in stationary factory equipment.

Therefore, those fuses did not satisfy the automotive requirements of the durability against mechanical vibrations and shocks, and of the endurance against on/off current cycles.

The first generation of hybrid vehicles used fuses that were derived from those used in large industrial machinery.

These circumstances led automotive design engineers to demand more compact fuses with mechanical durability and endurance against on/off current cycles which are required for electrified vehicles.

SOC was founded in 1958 as a specialized manufacturer of fuses.

Taking advantage of our expertise, we developed our own unique compact fuses with fuse-elements that have excellent mechanical durability and electrical endurance.

Since the early 2000s, we have continued to develop and provide fuses for circuit protection of hybrid vehicles (HEV) and electric vehicles (EV).

As the automotive industry entered into a revolutionary transition, notably towards electrification, the capacity and performance of on-board batteries increased.

As a result, the accidental short-circuit current has drastically increased.

This led to the need for over-current protection devices, such as fuses, with higher breaking capacities, voltage and current ratings.

SOC has designed and developed advanced fuse-elements with higher durability and interrupting capacity.

We have released the PT series with a rated voltage of DC 450 V and rated currents of 100 to 350 A.

These fuses have been widely adopted for over-current protection in a variety of applications.

Examples include: electric construction machines, traction batteries, high-voltage drives and auxiliary circuits used in EV/HEV.

As the EV/HEV battery technologies advance, larger-current and higher-voltage capabilities were required.

The PT4065 fuse was subsequently released to meet these requirements.

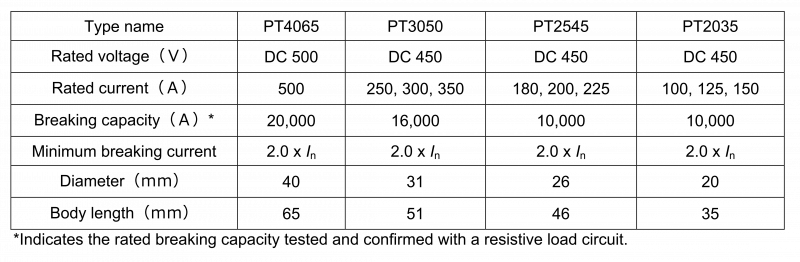

The PT4065 fuse can protect larger traction batteries with its rated voltage as high as DC 500 V, a rated current of 500 A and a rated breaking capacity of 20,000 A.

Construction

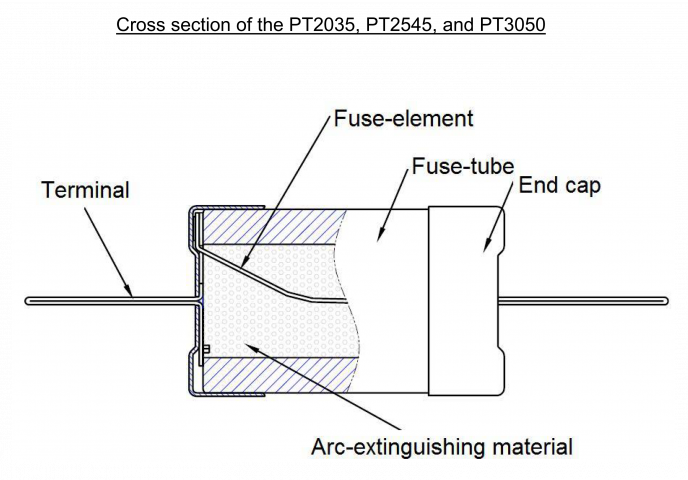

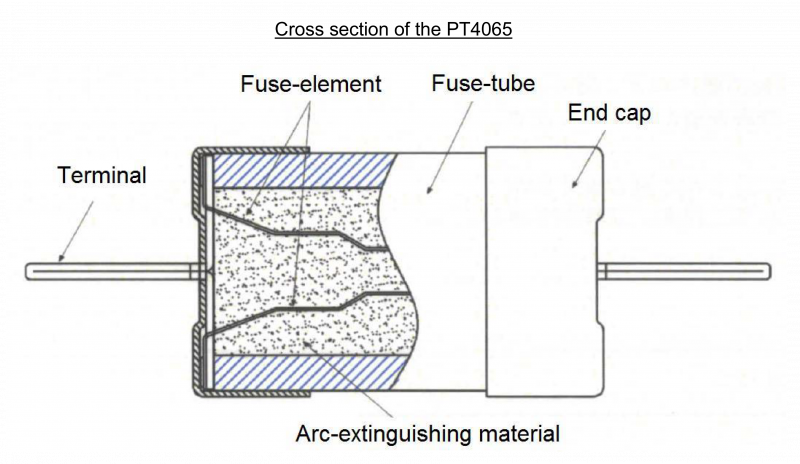

1. The PT series fuses consist of five different materials: terminals, fuse-element(s), ceramic tube, end-caps and arc-extinguisher.

These materials are carefully selected for high quality and performance.

2. The PT2035, PT2545 and PT3050 share the same construction.

They support a wide range of rated currents from 100 to 350 A.

The 4-digit number in the product name represents the approximate size (diameter x length) of the fuse body.

For example, the size of PT2035 is φ20×35mm.

3. The PT4065 fuse follows to the superior construction concept of the previous PT series, but adopts a two-piece symmetrical arrangement for the fuse element.

As shown below, the result is a fuse with a compact body size of φ40 x 65 mm and a current rating of 500 A.

Outline of specifications

The reasons for recommendation

SOC started developing small and lightweight DC fuses along with the emergence of switching power supply apparatus.

Ever since batteries began to be used in devices such as mobile phones and laptop computers, we have been leading fuse technology for DC circuit protection.

Based on those experiences and achievements, we have developed and released DC fuses used for protecting high-voltage batteries, harnesses and auxiliary equipment for EV/HEV.

Many of our products have already been adopted as automotive components.

Automotive fuses have to pass stringent reliability tests such as temperature & humidity tests, mechanical vibration & shock tests and pulse current cycle tests.

Well before the domestic and international standards on testing requirements for automotive fuses such as JASO D622-3 or ISO 8820-8 were established, SOC has been equipped with testing facilities to develop automotive fuses which satisfy the requirements of automotive customers’ reliability test standards.

The biggest advantage of the PT series is that it has a remarkably high breaking capacity that corresponds with advancements in electric vehicle and battery technologies.

Advancements in battery technology have increased the energy capacity and the output power of batteries, which is directly linked to the increase in the maximum short-circuit current in case of an accident.

Thus, a high breaking capacity, or the capability to safely break a large current, has become very important.

For this purpose, we have developed the PT series, which can meet the requirement of a high breaking capacity.

In EV/HEV, fuses such as the PT series and electromechanical relays are used as devices to control the on/off of the traction battery.

The role of the fuse is to cut off the abnormally large current such as a short-circuit current.

The role of the relay is to control the on/off of the traction battery at the time of turning-on and shutting-down of the power supply.

In the event of an accident where the relay cannot withstand a large current, leading to an explosion or a fire, the fuse operates to cut off the current and protect the safety of people and vehicles.

One of the key technologies in improving the breaking capacity of the PT series is our original design of the fuse element.

The PT series fuse element has carefully selected narrowed sections for the current path and forms a three-dimensional structure with bent sections, achieving high breaking capacity while maintaining durability and reliability despite its compact size.

The fuse-tubes of the PT series are made of inorganic ceramic material.

This material has higher temperature thresholds of softening, smoking, fire-catching and ignition than organic polymers or organic-inorganic composite glass epoxy, than other products on the market.

The selected material has higher mechanical strength and thermal conductivity than others.

Those superior properties of our material contribute greatly to improve durability, reliability, downsizing, a higher breaking capacity and a wide operating-temperature range (from -40 to 125 ℃).

Another key feature is manufacturing quality control.

Our automotive fuses, including the PT series, are mass-produced on dedicated production lines.

Our factories are certified according to the IATF16949 and ISO 9001 standards.

SOC is committed to satisfying all quality requirements from our customers.

Our PT series are recommended in your electric-vehicle design, together with our SMD fuses, like the 11CT and 25CF series for electric control units and circuits, as well as our high-voltage DC rated fuses like the 625, 1030 and 1040 series for auxiliary equipment.

We continue to monitor the evolution of higher voltage and larger current requirements and continue to develop high-performance fuses to meet the technical requirements of future EV/HEV.

Finally

In case you require the basic specifications, customization information and usage guide in designing your products safely or if you also need data from multi-physics simulations, reliability tests and prototyping tests for your design review of the products, please contact us.