How We Test Our Fuses

Technical Paper

Testing as Customer Service

We have accumulated technical expertise on electric measurement and analysis through our daily efforts to develop excellent fuses. We are ready to carry out, for example, short-circuiting tests of customers’ devices and protection-coordination tests.

Various test equipment is needed to succeed in reliable and timely fuse development. We use the following test equipment to swiftly accommodate customer requirements and develop fuses our customers can rely on. If interested, please do not hesitate to contact us.

Test Examples

1. Breaking Capacity Test

These test systems provides sudden overcurrent flows emulating short-circuit conditions to test the breaking capacity of protection components such as fuses by monitoring the time-dependent voltage and current profiles. SOC has eight test equipment systems for AC and DC breaking capacity tests. The electric power factor or time constant of an electric circuit, which can greatly impact current-interrupting attributes and protection coordination, can be adjusted upon request.

2. Overload Operation Test

These test systems provide controlled overcurrent to test the current-level dependent responses. The applied voltage during the test is carefully controlled because of its effect when the circuit opens. The current/voltage ranges cover all necessary conditions, including large currents as well as relatively small overcurrents, to comprehensively test all SOC products shown on the webpage. Safe operation of SOC products when they are used within the rated voltage and capacity are verified with these test systems.

3. Current-Carrying Capacity and Temperature Rise Measurement Systems

The current-carrying capacity measurement verifies that a fuse does not blow when a set current passes for a defined duration. In this case, the fuse will not operate (blow) so there is no need to apply the rated voltage. SOC has a system which can test current capacity for 2,000 A and over. The temperature rise of a fuse is measured when it is stabilized after the constant current flow. This is done in order to verify that the temperature rise for a defined current satisfies the specification.

4. Current On-Off Cycling Test

A defined level and waveform of current is repeatedly flowed through the device to evaluate its endurance. The current level, on/off time, and waveform can be adjusted upon request. Waveforms include rectangular and sinusoidal among others (see below).

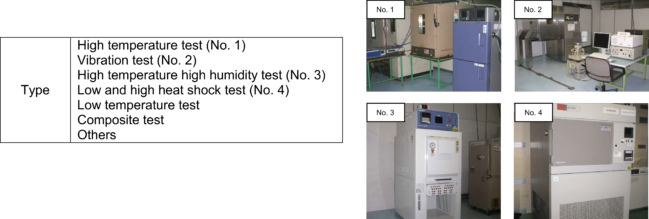

5. Environmental, Mechanical, and/or Electric Stress Tests

Devices are exposed to high temperature, low temperature, mechanical vibration or other harsh stresses to test the impact on device performance (see below). Test conditions such as temperature, humidity, and vibration can be programmed and changed. Also available are composite tests in which temperature/humidity, mechanical, and electric stresses are combined.

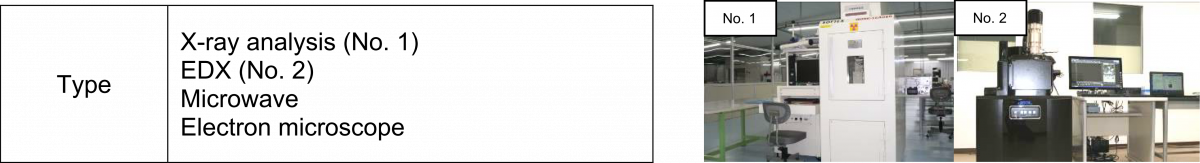

6. Analytical Equipment

The world is facing numerous environmental issues, and as seen in the Paris Agreement, these issues are a shared concern around the world. We have implemented environmental initiatives since our founding, and in our manufacturing process we remove flux without using any chlorofluorocarbon chemicals. We have equipment capable of conducting various analyses such as energy-dispersive X-ray spectroscopy (EDX) among others (see below). This analytical equipment is employed in the development of our fuses.